In-vehicle testing system for thermal validation of complete vehicles

Customer: Daimler AG

Area: Automotive industry / R&D

Requirements: In-vehicle measurement system with up to 1,000 measurement points via CAN bus or S-net

Implementation: Hardware: PC-104 system / software: LabVIEW

CarDiac test system

On measurement test drives for thermal validation of complete vehicles, development vehicles (prototypes and vehicles close to series production) are subjected to extreme thermal tests. Multiple teams, each specialized in specific technical areas, work in parallel on the vehicles under test, meaning that the software must be capable of recording a large number of measurement points during a single test drive. The CarDiac software developed for the former DaimlerChrysler AG as an in-vehicle testing system manages the entire data acquisition during the test drive. The data collection covers primarily temperatures, pressures, rotational speeds and the internal control device signals of the vehicles, which are connected to the system via CAN bus or other bus connections.

A rough description of a measurement test drive

Every measurement campaign is a logistically complex process in which many vehicles with prepared measurement systems must be transported to the measurement site. In order to make optimal use of the time available on the measurement tracks, careful planning is required for the vehicles and their components.

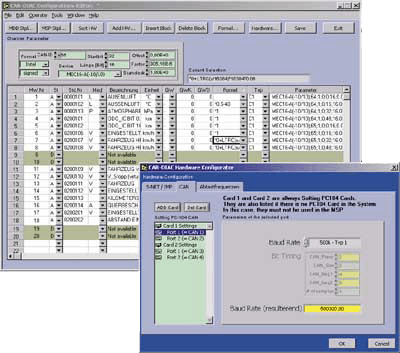

During the planning phase, the values to be recorded and their measurement points are defined at DaimlerChrysler with the assistance of the individual development teams. The measurement point plans are created on the basis of this description. These plans describe all channels to be recorded, including the measurement method and scaling. The final measurement configurations are divided up into groups so that each development team can filter out the measurement points relevant to them from the subsequent measurement data. At the respective test track, the prepared plans are loaded onto the measurement computer.

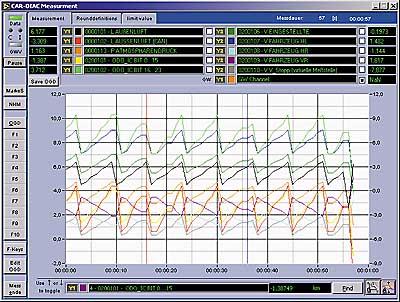

If necessary, the measurement point plans can still be expanded. For example, this is required in the event that vehicle components are replaced. Before the measurement test drive, the test engineer can load a defined number of display groups. This allows him to switch between measurement groups during the drive at the press of a button and to view their graphs directly. A limit value monitoring function evaluates important measurement points in the background and informs the driver if values fall outside of the defined limits.

After conclusion of a measurement, the system suggests a name to save the file under based on the vehicle information. Then the measurement file can be imported by the measurement computer for further evaluation.

In-vehicle measurement system

The measurement computer is a compact PC104 system that contains a number of open PCMCIA slots. The CAN driver integration created by measX makes it possible to integrate CAN cards of various manufacturers into the software. MEC modules (Mestec), SIM modules (IPETRONIK) via CAN and IMP modules (Solartron) via S-net are used for the temperature recording. The S-net control is implemented with an integrated ISA expansion card of the PC104 system.

The application

The project was realized with National Instruments LabVIEW 7.0. After the program is started, all program functions can be accessed from a menu bar. The individual modules and their primary functions are briefly described below:

CarDiac preparation:

- Creation of the measurement point plan by entering measurement points or selecting existing ones from the database

- Creation of calculated measurement points

- Configuration of the hardware required for the measurement

CarDiac measurement:

- Data acquisition

- Limit value monitoring

- Overview of the min/max and mean values over time

- CarDiac analysis

- Subsequent viewing of the measurement

- Automated generation of multiple reports

- DIAdem export

Online group editor:

- Creation of user-defined groups that should be shown in the display

- Configuration of the display of the individual groups

Filter editor:

- Creation of filter files that permit the filtering of specific measurement channels out of the entire measurement so that evaluations can be restricted to only these channels

Measurement documentation data editor:

- Compilation of the data describing the vehicle

Variant comparison:

- Comparison of individual measurement points from a large number of measurements

- Excel export, allowing the user to process the collected values using Excel macros

The advantages at a glance

- Rapid creation of a measurement configuration by filtering measurement points available in a database.

- Flexible CAN connection thanks to open hardware selection.

- Support for up to 16 CAN ports

- Option to export to DIAdem format for additional offline evaluations

- Up to 1,000 measurement points via CAN bus or S-net

- Thanks to modular programming, additional data collection modules and alternative hardware can be integrated extremely quickly.