Automation of a spinning pump test bench with DASYLab

Customer: Solvay Acetow GmbH

Area: Mechanical engineering / production

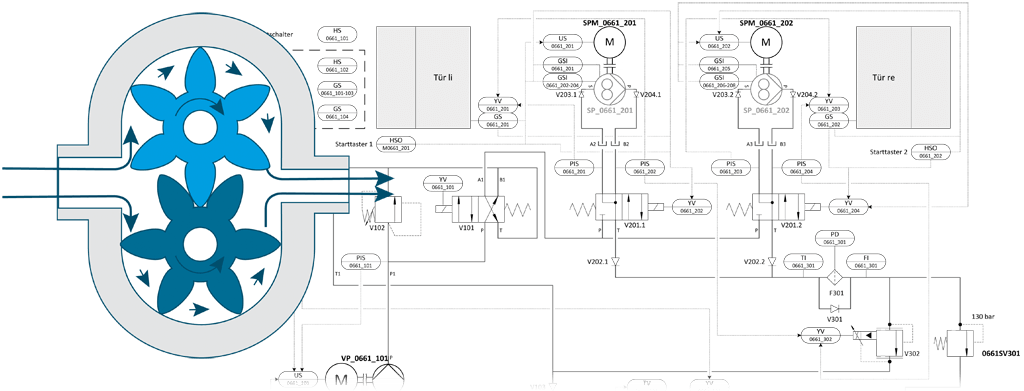

Requirements: Automation of a test bench for various types of high-precision gear wheel feed pumps

Implementation: Software: DASYLab

An elegant solution

As user-friendly software for measurement and testing applications, DASYLab has a large user base. In the case of especially challenging requirements, measX creates the worksheets for its customers.

DASYLab now enjoys a solid position in many companies since the software allows almost all testing, control and regulation tasks to be implemented purely graphically, without any programming knowledge. If it is necessary to realize especially complex automation tasks in DASYLab, however, deeper knowledge of the program and its capabilities is required. In such cases, modules and data flow lines are not sufficient to describe the task. It is necessary to implement global variables and event-driven actions. Depending on the scope of the task, measX can create the base worksheet for the customer to continue working with on its own.

The automation of a new spinning pump test bench for Solvay Acetow GmbH was a technical challenge even for the DASYLab experts in Mönchengladbach. Various types of high-precision gear wheel feed pumps had to be measured and tested.

Complex step sequences

The pump test bench, for which measX also supplied the hardware, consists of two testing stations. While testing is taking place at one station, a new test specimen can be mounted at the other. “The actual test procedure, a pressure holding test, was easy to implement in DASYLab. Much more complicated was the procedure control, including user interface. This was due in particular to the staggered sequence of mounting, testing and removing the test samples,” reports project manager Stephan Gerhards. The specified step sequence of instructions had to be transferred to a DASYLab worksheet that by default only depicts simultaneous processes. Stephan Gerhards solved this problem with a little trick. The individual sub-sequences were realized in separate black boxes for each condition and each testing station. Within each black box, a suitable combination of trigger modules and relays are used to check whether or not the current step sequence step should be carried out. In this way, the parallel processing of all DASYLab modules was “forced” into a serial arrangement.

The experts at measX worked very closely with Solvay while creating the worksheet. For this purpose, measX created a small hardware simulator that could simulate all inputs and outputs of the hardware. This made it possible to directly test and optimize all procedures independently of the test bench.

Download X-Press with the report as PDF